Projects and Case Studies

A key component of the MultiGen system is the MultiChill Chiller developed by Cooltec in the USA that now forms part of the MultiChill Technologies MultiGen System. The following are some of the projects CTI and WES were involved in as the product was developed. There follow a series of specific operating experience examples including some Client quotations.

The MultiChill 5 RT unit demonstrably meets or exceeds its performance specification, operates reliably and with low maintenance requirements and works in an exhaust heated CCHP environment. Details are also given of independent performance checks to verify that specified outputs are achieved.

UNITED STATES - BROOKLYN, NY

Project Description:

This project was a rooftop installation at a machine shop in a residential neighborhood. There were noise restrictions to be adhered to for this install. Supported by Keyspan Energy (Brooklyn Union Gas)

Specifications:

MultiChill 25RT

A/C Performance:

Sequence controller, Skid mounted, Reduced noise and vibration

Economic Impact – Chillers:

76,400 kW annual demand reduction 36% operating savings, 4.3 year payback

UNITED STATES - HYANNIS, MA

Project Description:

Installed at Kennedy Museum. Specified by city for energy efficiency; hot water heat, no previous a/c; lower cost installation; supported by Keyspan Energy

Specifications:

MultiChill 15RT/20RT

A/C Performance:

35RT, Skid mounted, sequence controller, multiple zones

Economic Impact – Chillers:

67,000 kW annual demand reduction, 29% operating savings

UNITED STATES - YORBA LINDA, CA

Project Description:

Residential installation in Southern California. Data acquisition sponsored by GTI: 4 comfort zones along with 2 subzones; cost effective installation.

Specifications:

MultiChill 10RT

A/C Performance:

Sequence controller, 6 comfort zones

Economic Impact – Chillers:

33,000 kW annual demand reduction, 50% operating savings, 4.1 year payback

MEXICO - CULIACAN, MX

Project Description:

Residential building rooftop installation. 1-3 units per home; Propane distributor used as economic reason to install propane.

Specifications:

MultiChill 55RT

A/C Performance:

Dedicated multiple zones

Economic Impact – Chillers:

254,000 kW annual demand reduction, 29% operating savings, 4.1 year payback

MEXICO - culiacan, mx

Project Description:

Commercial building rooftop installation. Propane fuel; rehab with no previous a/c; cost effective installation; substantially increased summer propane use. 1-3 units per home; Propane distributor used as economic reason to install propane.

Specifications:

MultiChill 45RT

A/C Performance:

Dedicated multiple zones

Economic Impact – Chillers:

254,000 kW annual demand reduction, 29% operating savings, 4.1 year payback

AUSTRALIA

Project Description:

Exhaust heat fuel source. Installed to supply electric power from Capstone Turbines, water from the air, and air conditioning.

Specifications:

MultiGen 10RT

Case Study Australia

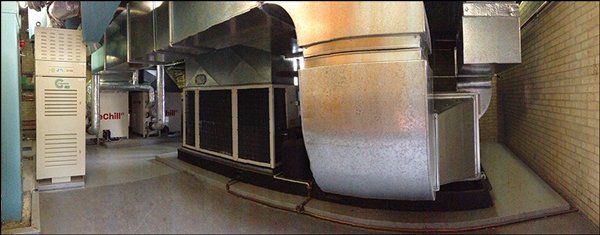

UNITED STATES - canton, oh

Project Description:

Exhaust heat fuel source from one of two Capstone Microturbine 30s. Installed to supply electric power, office air conditioning, and natatorium water heating.

Specifications:

Capstone 30kW, MultiChill 5RT, UniGen Exhaust to Water Heater.

| Additional Locations | Capacity | Exhaust/Gas | Application/Comments |

|---|---|---|---|

| Gaz de France | 5RT | Gas | Prototype performance testing, GdF R&D facility, sponsored by GdF |

| California Process Cooling | 10RT | Gas | Mfg process; 5 days – 18 hrs; replacement for poorly performing competitive units |

| Cooltec, Columbus, OH, USA | 20RT | Exhaust | Performance monitoring; durability testing |

| AMTI, Boston, MA, USA | 10RT | Gas | Testing proprietary corrosion inhibitor |

| GTI, Chicago, IL, USA | 5RT | Gas | Environmental lab testing for durability (4,000+hrs) |

| SoCal Lab Testing, USA | 5RT | Gas | Independent study |