Contact MultiGen

To Get Clean Drinking Water

World Environmental Solutions Pty Ltd

MultiGen Solutions Group / Australia Toll Free: 1 300 667 963 / International: +61 410 403 888

World Environmental Solutions Pty Ltd

Australian Project

Client:

Government Educational Institution in Australia

Key Project Statistics:

- Electricity is generated on-site 24×7 at $0.175/kWh saving almost $0.20/kWh compared to grid supplied

- Estimated Annual CO2 Savings: 350 tonnes

- Estimated Annual Savings: $100,000

- Estimated Payback: 4.5 years

- Gas Consumption:

- 888MJ/Hour (MicroTurbine)

- 94MJ/Hour (Each Absorption Chiller – ‘*if required’)

- * The chillers exclusively use waste heat from the MicroTurbine.

Project Description:

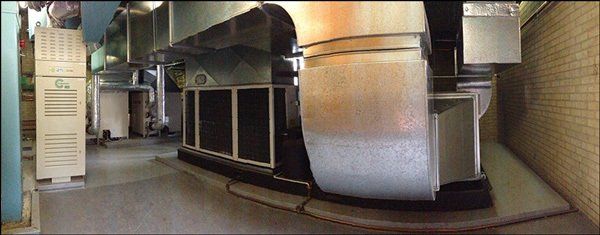

Replace a highly inefficient HVAC system. Install a MultiGen system to meet HVAC requirements, generate on-site power to supplement existing grid load, produce water to supplement irrigation and provide air conditioning. Decommission and remove old equipment including a vapour compressor, condensers, air handling unit and electric duct re-heaters.

Project Installation Contractor:

Stallion Air Conditioning Sydney, Australia

MultiGen Model:

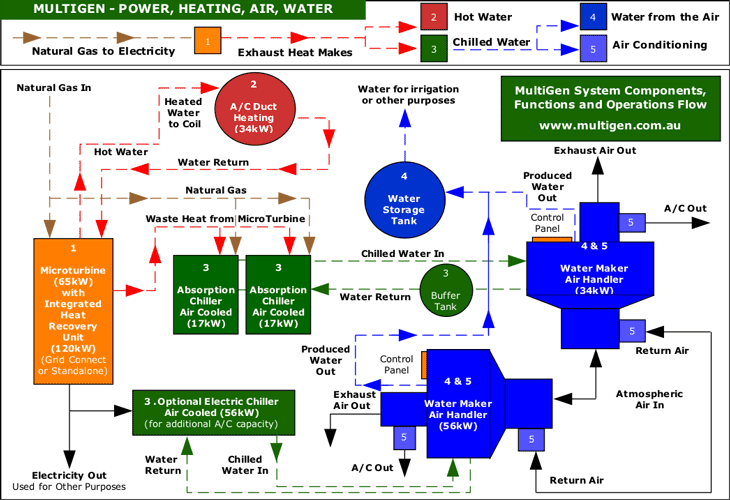

MultiGen65 90kWr – Power, Hot Water, Chilled Water, Air Conditioning and Water from the Air

Functions:

- Electricity Generation

- Hot Water and Chilled Water Production,

- Air Conditioning and Water Making from the Air

Pre-Project Statistics:

- Hourly Electricity Consumption of Plant: 60-90kW (Higher energy consumption when 5 electric duct mounted reheaters were in operation)

- HVAC Capacity Requirement: 90kW

Post-Project Statistics:

- Plant Consumption: 20kW

- On-site Electricity Generation from MicroTurbine: 65kW

- Free Cooling from Waste Heat Chillers: 34kW

- Free Heating from Waste Heat Recovery Unit: 34kW

- Additional Electric Chiller: 56kW

- Noise Level: <65Dba

- MicroTurbine Emissions Data: 15% O2 NOX4-9ppm , C0-30ppm

- Absorption Chiller Emissions: 6.5% O2, CO-30ppm, 8.2% CO2, Ratio: 0.0004

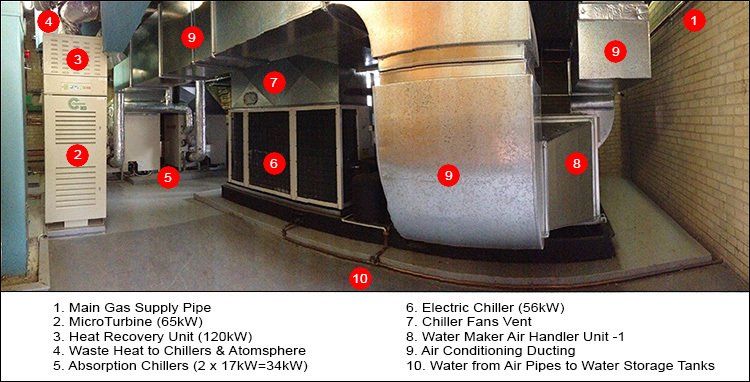

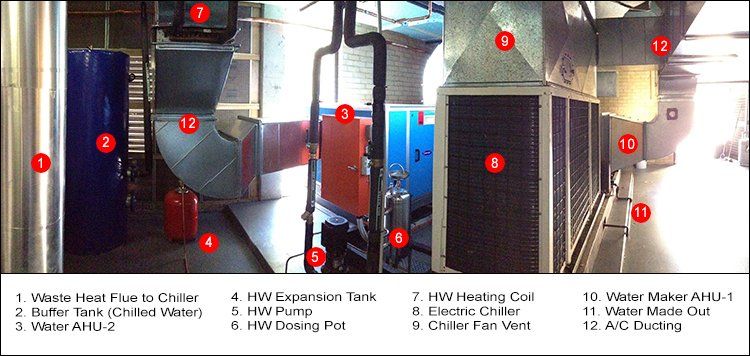

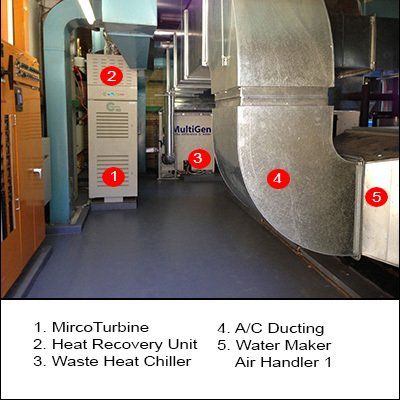

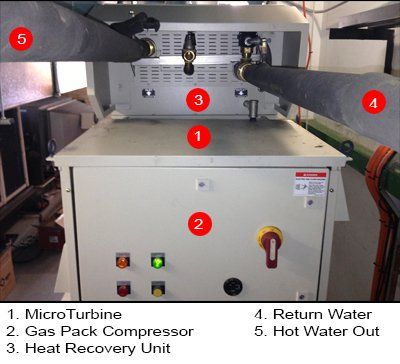

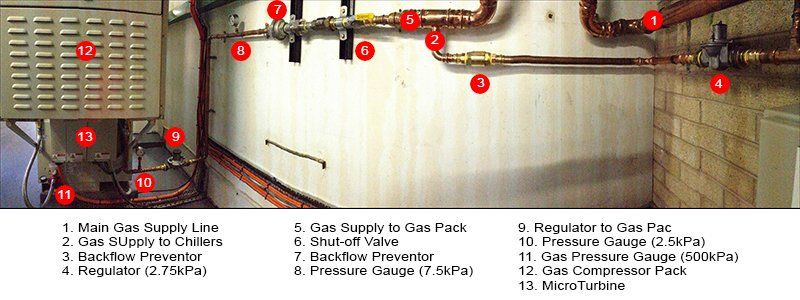

MultiGen system comprises of:

- 1 x 65kW Gas Powered MicroTurbine with an Integrated Heat Recovery Unit and Gas Compressor

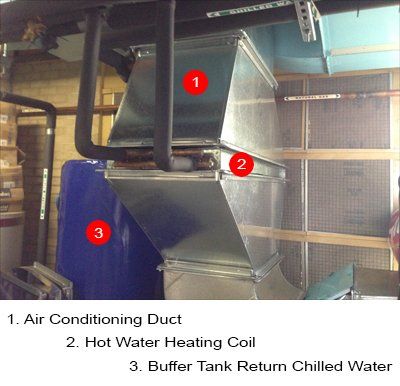

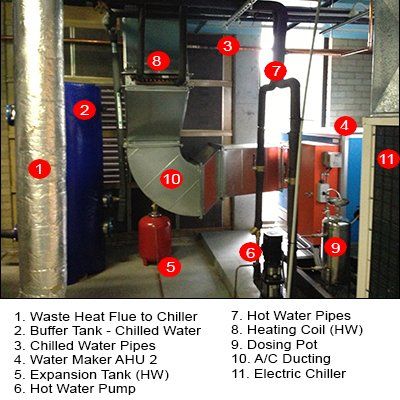

- 1 x Hot Water Heating Coil fitted to the A/C Ducting, Expansion Tank and Roof Mounted Dump Cooler

- 1 x Dual Mode Controller for Grid Connect or Standalone Operation of the MicroTurbine

- 2 x 17kWr Dual Fired (Waste Heat and Gas) Air-Cooled Absorption Chillers with Buffer and Expansion Tanks

- 1 x 34kW Water Maker Air Handler

- 1 x 56kW Air-Cooled Electric Chiller with Buffer and Expansion Tanks

- 1 x 56kW Water Maker Air Handler

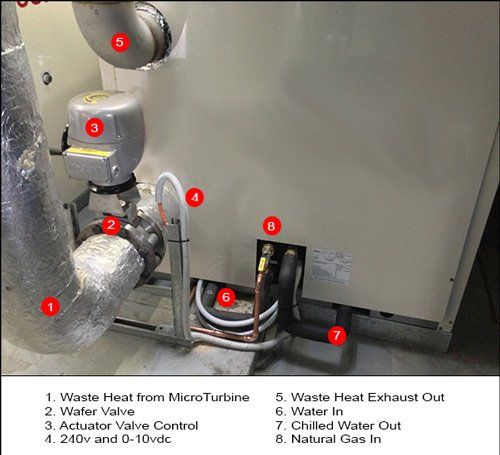

- 3 x Wafer Style Flue Valves with Actuators to Control Waste Heat

MultiGen System Operation Overview:

The MicroTurbine is supplied with natural gas and generates 65kW of electricity 24 hours a day. The electricity generated supplements the Institute’s business hours electricity supply grid load of 140kW and provides all electricity out of business hours approximately 50kW per hour. The MircoTurbine is connected to the Institute’s Building Management System to enable load-following and monitoring of gas consumption and electricity generation. The MicroTurbine has the capacity to operate, via the Dual Mode Controller, to follow a load of Stand Alone in the event of a grid failure.

The waste heat from the MicroTurbine is used to heat water through the integrated Heat Recovery Unit for 34kW of space heating. When cooling is required the waste heat is used to initiate chilled water from the Absorption chillers for 34kW of space cooling. The electric chiller provides the additional 56kW of cooling and heating required.

If heating or cooling isn’t required the waste heat is exhausted to atmosphere. The Water Maker Air Handler units make 5litres of water per hour per 3.6kW of cooling capacity when the temperature is 27c with relative humidity of 60%. The Water Maker Air Handler’s water production capacity varies according to local climatic conditions.

The Absorption Chillers are dual fired, air-cooled and use ammonia as the refrigerant. They have 3 modes of operation:

- Waste heat only

- Natural gas only

- Waste Heat and Natural Gas

If the MicroTurbine is not operational the chillers can use natural gas. The MicroTurbine normally provides the necessary waste heat for the chillers. Up to 4 Chiller can be coupled to one 65kW MicroTurbine. In the event that the waste heat is insufficient natural gas is used to maintain the desired operational temperature of the Chillers.

All components require minimal maintenance. The gas appliances that form part of MultiGen system, the MicroTurbine and Absorption Chillers, have been inspected and certified that they comply with strict Australia standards specifically:

- AS 3814 – Gas Appliances and,

- AS 4625 – Electronic Flame Safeguards and Flame Detectors.

Project Photo Gallery

-

Button

MultiGen Components

-

Button

MultiGen Components

-

Button

Functional Diagram

-

Button

HVAC System Replaced

-

Button

Installing MultiGen

-

Button

MicroTurbine + Gas Pack

-

Button

Water Maker Air Handler-2

-

Button

Absorption Chillers

-

Button

Heat Recovery Unit

-

Button

Components

-

Button

HRU and Gas Pack

-

Button

Gas Train

-

Button

Type B Approved Appliance

-

Button

Hot Water Circuit

-

Button

Duct Heating Coil

-

Button

HW Expansion Tank

-

Button

Water Maker AHU-2

-

Button

Dump Cooler HW Circuit

-

Button

Exhaust Control Valves

-

Button

Control Valve-Atmosphere

-

Button

Waste Heat Valves

-

Button

Water from the Air

-

Button

Water Maker Air Handler-1

-

Button

Dual Mode Controller

-

Button

Absorption Chillers

-

Button

Absorption Chiller Fans

-

Button

Chillers Certified

Australia

Brisbane Office and Warehouse

(Contact by info@multigensolutions.com.au)

World Environmental Solutions. Australian Headquarters

7 Macwood Road

Smith Lake

NSW 2428

Australia Toll Free: 1 300 667 963

International: +61 410 403 888

All Rights Reserved | World Environmental Solutions Pty Ltd.

MultiGen was developed by World Environmental Solutions Pty Limited an Australian company that retains the exclusive rights to market, distribute and manufacture in Australasia.